A time-lapse video showing the stages of screeding the floor in St Mary’s Church. We completed this job at the end of March this year.

Spotlight on our team 🌟

Sarah Woodger is our Director of Operations, our company Mum, and our style queen 👑

Sarah has worked with The Limecrete Company since March 2015 and is incredibly enthusiastic, passionate, and knowledgeable about Limecrete Flooring and its benefits.

She is logical, forward thinking, creative and runs our company with integrity and authenticity.

Sarah is always willing to answer any questions or queries people may have, and runs our online CPD sessions.

Outside of work, Sarah’s interests include, spending time with her friends and family, collecting vintage clothing, music, dancing and playing scrabble.

St Mary’s Parish Church, Prittlewell

Spotlight on our fabulous team

Stephen and Carol Catchpole – Owners and Directors of The Limecrete Company

Stephen and Carol Catchpole are a husband and wife team and owners of The Limecrete Company since 2020. They both love the ethos of the product and knowing the huge benefits that a limecrete floor can make to a property.

Stephen, MD and also a farmer, has a practical and logical mind. He is our chief fixer and responsible for keeping the wheels turning!

Carol has been instrumental in streamlining our company and bringing in efficiencies. Carol is our marketing guru and motivator with a mind for further growth!

In their spare time Stephen and Carol like to explore new places, walk and cycle. Stephen plays squash and Carol rides. A huge highlight for them last year was travelling to Canada, hearing whale song and seeing bears.

10 Magic Ingredients to building a Limecrete Floor 🌟

RFG – This creates a load bearing substrate. It insulates and forms a capillary break. It is also a sustainable material made of a waste product.

Geotextile Membrane – This separates the substrate and limecrete from the insulation layer.

Aggregate – Depending on the requirement this would generally be a sharp sand or 0-15mm pumice.

Geogrid – When using UFH this provides a grid for the pipework to be attached to.

Fibres – 6mm polypropylene fibres help to increase the strength of the limecrete and decrease cracking.

Cork or Foam Edge – This essential detail separates the wall from the limecrete, ensuring no thermal bridge and that both have their own independent moisture vapour transfer.

Water – As the lime we use is NHL5, the addition of water initiates the hydraulic set. Limecrete is ready for light footfall after 72 hours.

Lime – We use NHL5, the strongest of the natural hydraulic limes, which ensures the strength that is required for ground bearing slab is created.

Volumetric mixer – Mixes Limecrete with consistency, speed and efficiency.

Our fantastic team 💖 – Hardworking, passionate and highly regarded!

Tithe Barn – Whittington Court

A new Limecrete floor being installed at the absolutely stunning Tithe Barn, Whittington Court. The first step in creating a magical wedding venue! We are so excited to follow the beautiful Tithe Barn’s progress! www.whittingtoncourt.co.uk

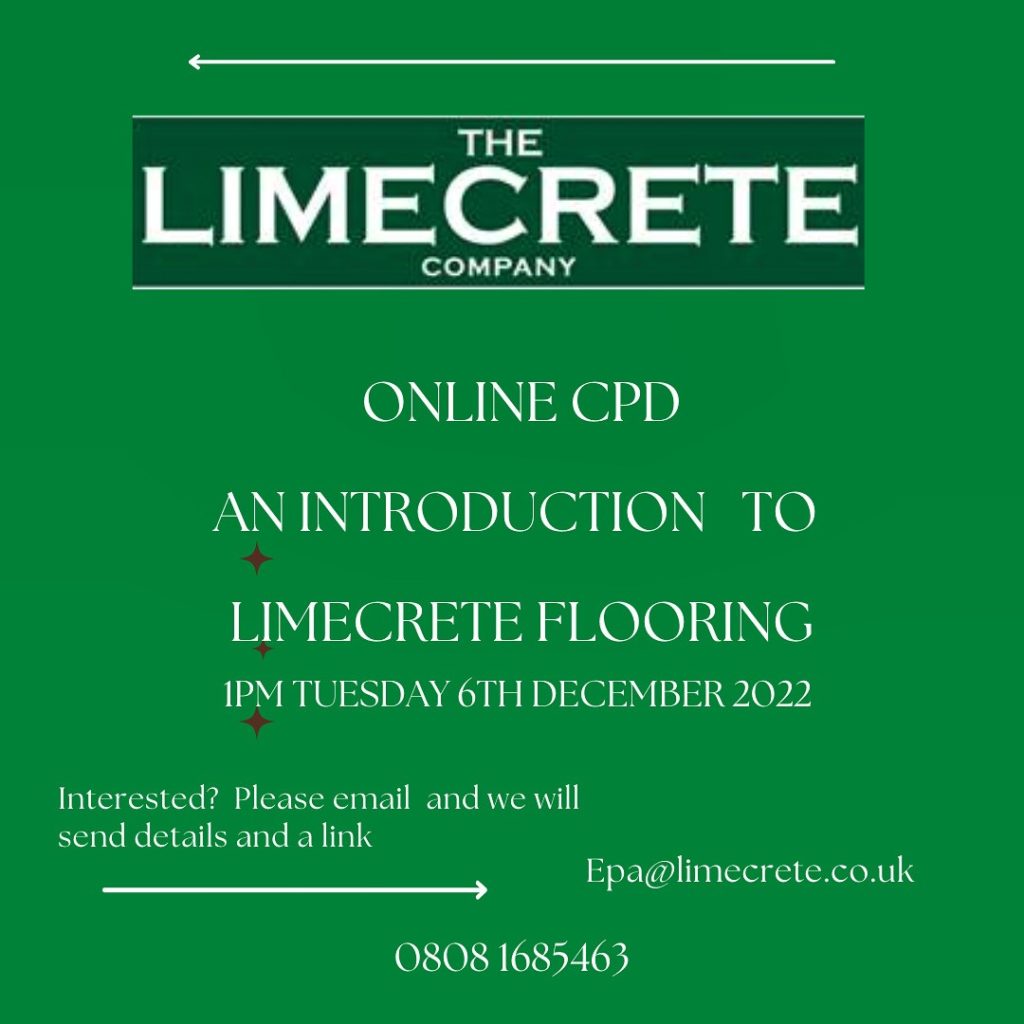

CPD Online – An Introduction to Limecrete Flooring

3 Steps towards a limecrete floor in The Great Barn

Here is clearly displayed the first 3 stages of a limecrete floor in this wonderful old clay barn in Wiltshire

Ready for the terram to be laid on top of the soil to create a clear barrier between soil and recycled foam glass. This will prevent any moisture wicking through the recycled foam glass into the limecrete.

Here the recycled foam glass has been laid over the terram, with the sides lapped up slightly.

All ready for the under floor heating pipes to be clipped into place by the customer’s heating company. We will return soon to lay 100mm screed.

Sometimes it’s not big open floor areas, even in a church.

Penllyn Castle in Wales – Floors completed The Limecrete Company – Awesome!

Click here for a link to a great little video on this project: https://www.instagram.com/reel/CeQKWi1qDAR/?utm_source=ig_web_button_share_sheet

Another amazing project to have the honour of laying limecrete floors within – Penllyn Castle. This is being renovated in a totally sympathetic and careful manner using both traditional and modern methods, a real credit to the owners. Thank you for using The Limecrete Company